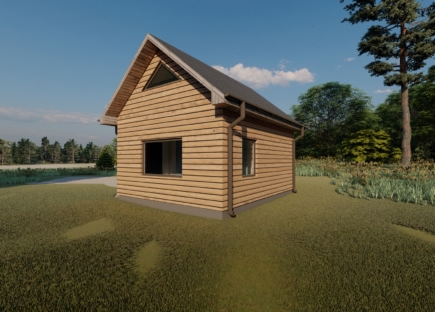

PRODUCTION OF SIP PANELS

For construction of residential buildings, cottages, garden houses, garages and outbuildings

Here with us you are not just buying a set of panels or building a house, but a personal assistant and construction consultant, at all stages of your order.

5 reasons to choose a house of SIP panels

High construction speed - SIP panels are the building materials, completely ready for assembly. Due to the simplicity of their installation, a team of 4 people will finish all the work in 1-3 weeks. Moreover, houses of SIP panels can be built at any time of the year, and winter construction will save you money.

Comfort throughout the year – the SIP-panel houses are cool in summer and warm in winter. Compared to standard materials, they retain heat much more efficiently and significantly reduce heating costs.

Saving your budget - due to low weight, the SIP panels have low pressure on the base, which allows the use of pile or strip shallow foundations. This solution reduces the labour costs and the material consumption.

Durability - all the materials we use (CBPB boards, mineral wool or expanded polystyrene) have high performance - they do not wear out, retain their dimensions and shape, do not rot. All this guarantees that a house made of SIP panels will serve you for at least 50 years.

Light and large rooms - the small thickness of the panels visually enlarges the space and fills it with light. In the thick-wall houses, the windows look like loopholes and therefore they have to be increased. In a house made of SIP panels, even small windows provide enough light.

SIPEX products

Panel size

The OSB-3 panels height may be 2.5, 2.8 and 3 meters. The panels are produced only of the whole OSB sheets, while the CBPB panel height is 3.2 meters. This allows to solve any clients’ tasks as for the desired height of the walls (ceilings).

Heat insulation

Mainly expanded polystyrene with the addition of graphite is used for insulation of panels; this makes the panels warmer, more fireproof and not interesting for rodents. The use of mineral stone wool is possible as well.

Not only OSB

Now only SIPEX, in Europe, offers panels with cement-bonded particle board (CBPB). This material is 65% cement, which makes the material more flexible in various construction applications, moisture resistant, fireproof, bioneutral and environmentally friendly.

Construction technology

In addition to the SIP panel production, SIPEX is engaged in the design and construction of houses made of the SIP panels. We build houses according to ready-made projects or develop an individual project for the Customer, considering all requirements. The construction may take place at any time of the year.

Each Customer is guaranteed an individual approach and high-quality work at all stages of the order performance. We use only the guaranteed high-quality materials and the modern engineering solutions.

Foundation

The use of SIP panels as the main building material allows to build houses on any type of foundation - slab, strip, rotary bored cast-in-place piles or concrete driven piles.

Walls

The SIP 174 or 224 mm thick panels are used for external walls, while the 124 or 174 mm thick panels are used for internal walls. The dry planished square timber or the glued beams with polystyrene filler are used as the connecting materials.

The graphite polystyrene foam or stone mineral wool is used as the heat insulating material.

Flooring

The SIP panels or H-beams can be used in floor slabs, interfloor or attic floors. We use the heat insulating material of our own production as a soundproofing material.

Front elevation

SIP panels allow to finish the facade using any known technology - a “wet” facade, imitation of timber, a ventilated facade with wood trim, fiberboard or siding.

Roof and roofing

Roofing is made using the SIP panels or H-beams. As a roofing material, it is possible to use metal tiles, bituminous or ceramic tiles, seam roofing or built-up bituminous felt.